Mga spotlight

Boring Machine Operator, Cabinet Maker, Knot Saw Operator, Lathe Operator, Machine Operator, Molder Operator, Router Operator, Sander, Sander Operator

Humans have been making things out of wood for almost as long as we’ve existed! Wood is abundant, sturdy, and useful for a wide range of things. But it wasn’t until we invented saws and other cutting instruments that woodworking really took off!

Today, we have an array of powered machinery to cut, smooth, and shape wood for furniture, cabinets, and other products. But it takes highly trained Woodworking Machinery Operators to use these types of equipment to craft raw wood into finished pieces or parts.

From band and circular saws to drill presses, lathes, and milling machines, they must be proficient in safe machinery operation techniques to avoid any mishaps while they work! In addition, they have to understand the properties of the wood they’re working on. They frequently collaborate with designers and craftsmen to understand the exact requirements for the items they’re going to produce.

- Creating tangible, often artistic wood products

- Steady work in furniture, construction, and custom woodwork industries

- Independence to work on pieces at individual workstations

Oras ng trabaho

- Woodworking Machinery Operators typically work full-time, and must frequently travel to job sites. They may work overtime when collaborating with construction teams on larger projects.

Mga Karaniwang Tungkulin

- Review project drawings, blueprints, or schematics

- Set up manual and Computer Numerically Controlled (CNC) woodworking machines, such as drill presses, lathes, shapers, routers, sanders, planers, and wood-nailers

- Program basic instructions into computerized machines using G-code, computer-aided manufacturing (CAM) software, or machine-specific programs

- Examine woodstock to make sure it conforms to requirements

- Position wood pieces correctly and securely before working on them

- Operate machines safely, according to manufacturer instructions

- Monitor machine operations for problems or signs of instability, such as excessive vibration. Adjust controls as needed to ensure proper performance

- Use hand tools as needed to put the finishing touches on products

- Check finished workpieces to ensure quality (including the correct shape, smoothness, and other specifications). Use measuring instruments such as rules, calipers, templates, and gauges

Karagdagang Pananagutan

- Conduct routine maintenance on woodworking machinery (i.e., cleaning, oiling, and replacing old parts)

- Wear proper personal protective equipment such as goggles, gloves, masks, or hearing protection

- Train and mentor new operators

- Maintain a clean workstation

- Document work procedures, as required

Soft Skills

- Accuracy

Alertness - Analitikal

- Maingat

- Nakatuon sa pagsunod

- Kritikal na pag-iisip

- Mabusisi pagdating sa detalye

- Disiplina

- Excellent hand-eye coordination

- Manu-manong kagalingan ng kamay

- Pagsubaybay

- No severe dust allergies or breathing issues

- pasensya

- Pagpaplano at organisasyon

- Pagtugon sa suliranin

- Pagtitiyak ng kalidad

- Kaligtasan-isip

- Mukhang makatarungan

- Stamina

- Malakas na kasanayan sa komunikasyon

- Pamamahala ng oras

Teknikal na kasanayan

- Machinist programs like Machinist’s Calculator

- Computer-aided design programs like Autodesk AutoCAD

- Computer-aided manufacturing software like Autodesk Fusion 360

- Industrial control software such as EditCNC

- Procedure management programs

- Tools and equipment such as micrometers, vernier calipers, lathes, milling machines, shapers, grinders, drilling machines, cutting tools, etc.

- Fundamental knowledge of hydraulic systems, electrical wiring, lubricants, and batteries (for portable or cordless tools)

- Familiarity with various types of wood

- Personal protective equipment (PPE)

- Furniture and related product manufacturing

- Wood product manufacturing

- Self-employed workers or contractors

Woodworking Machinery Operators are relied on to produce products that conform to very specific requirements. Thus their work must be meticulous, even under pressure to meet deadlines.

They have to take into consideration multiple factors, including what types of wood can be used with which types of equipment, and how best to cut or shape the wood.

The working environment can be loud and hazardous, requiring workers to wear protective gear, such as goggles and hearing protection. They must carefully follow safety procedures to avoid injury to themselves or others in the area.

The day-to-day job requires stamina because workers are usually on their feet, often in bent or leaning positions. The repetition can get monotonous after a while, but workers have to keep their focus because of the inherent risks of the job so they don’t get hurt!

The woodworking industry is increasingly embracing automation and CNC technology, significantly enhancing precision and productivity! CNC routers and lathes are helping to facilitate more complex designs, transforming the sector into a more efficient, versatile field.

Alongside technological advancements, there’s also a growing emphasis on sustainability. Customers have more focus on eco-friendly materials and practices in general, such as buying products made from recycled wood or responsibly sourced timber.

Another trend is thanks to the advancements in software like CAD and CAM, which are not only revolutionizing design and production processes but also streamlining operations.

People who get into machine-related career fields usually enjoy working with their hands and feel comfortable using tools and stationary heavy equipment. They might have enjoyed math and computer programming courses in high school or liked doing projects in shop classes.

Woodworking Machinery Operators can collaborate with others but don’t mind being on their own for long periods. They might have been very independent growing up and may have always wanted a job where they have some freedom to do their work without a lot of interaction with others.

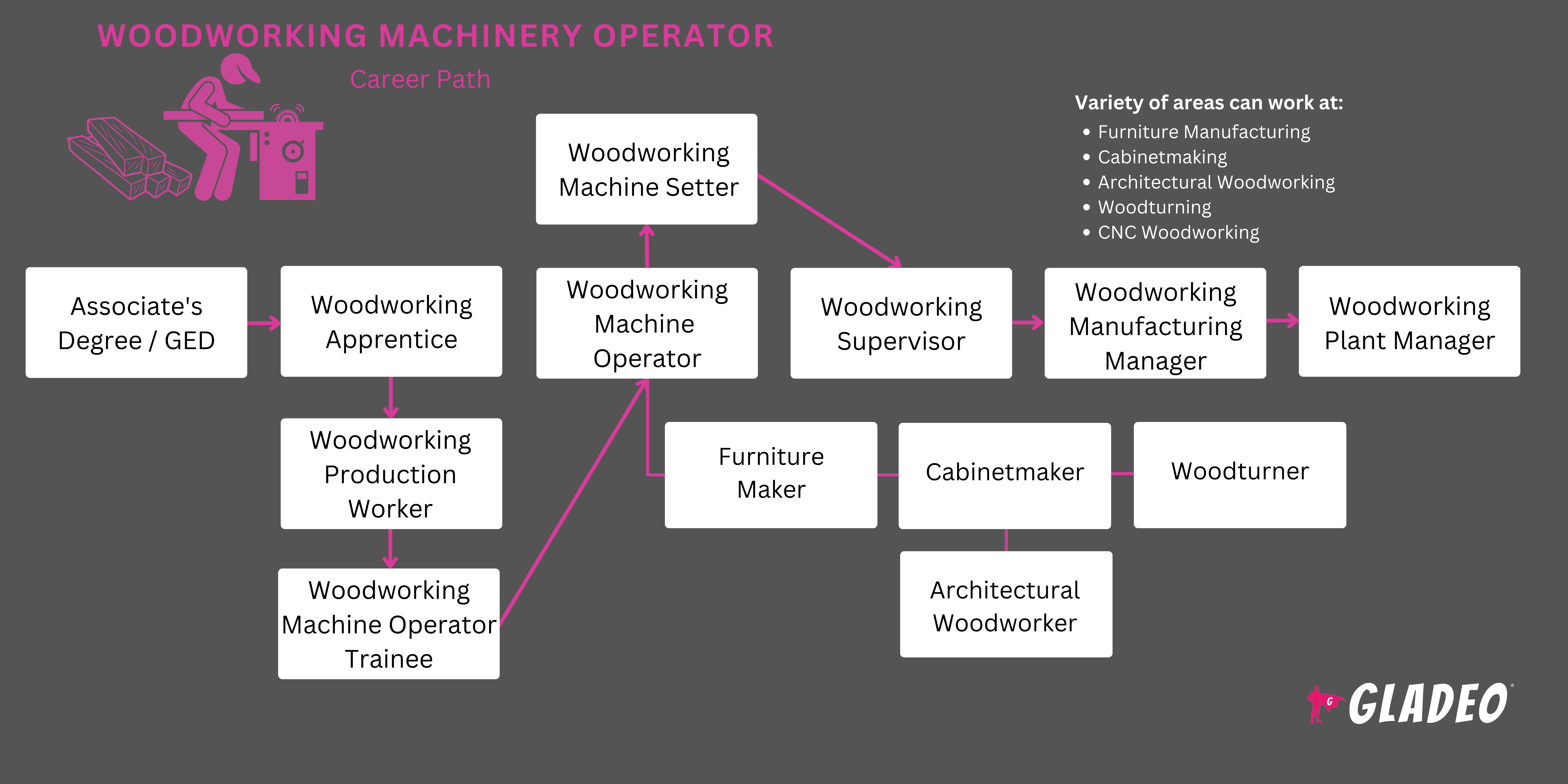

- Woodworking Machinery Operators need a high school diploma or equivalent. A college degree is not necessary

- Workers must have applicable woodworking, carpentry, or construction skills. These can be learned in high school, via vocational courses, apprenticeships, or part-time jobs

- Some start as helpers or laborers, learning how to safely use hand and power tools before moving on to larger equipment like CNC machines

- Operators may need to program their CNC machines, so having some knowledge of basic computer applications is useful

- In addition, certain types of math are commonly used in this profession, such as basic arithmetic, geometry, fractions and decimals, measurement conversions, basic algebra, trigonometry, and proportions and ratios

- Operators can apply for credentials from the Woodwork Career Alliance of North America such as:

- Sawblade Certificate: Focuses on introducing fundamental woodworking skills and safety knowledge

- Green Credential: Covers basic woodworking operations and safety practices

- Blue Credential: Involves advanced skills and knowledge in woodworking techniques and machinery operation

- Red Credential: For demonstrating proficiency in a range of woodworking machinery and techniques

- Gold Credential: Represents a high skill level in woodworking, encompassing advanced machinery operation and complex techniques

- Diamond Credential: Indicates mastery of woodworking skills and extensive experience in the industry

- Workers also may benefit from obtaining CNC machine certification via community colleges and directly from machine manufacturers!

- Safety is an integral part of the job, so an OSHA Safety and Health

Fundamentals Certificate or OSHA 10-hour training card can be helpful. Employers can usually explain the details and help workers get signed up!

- Woodworking Machinery Operators don’t need to go to college, but if you do take classes, consider the cost of tuition, discounts, and local scholarship opportunities (in addition to federal aid)

- Isipin ang iyong iskedyul at kakayahang umangkop kapag nagpapasya kung mag-e-enroll sa isang on-campus, online, o hybrid na programa. Sa isip, gusto mo ng maraming hands-on na pagsasanay na maaari mong makuha para sa marami sa mga kursong ito

- Basahin ang mga review mula sa mga nakaraang mag-aaral at tingnan ang mga istatistika ng placement ng trabaho at mga detalye tungkol sa alumni network ng programa

- Tandaan, ang ilang mga programa sa pagsasanay ay maaaring may mga koneksyon sa mga lokal na employer!

- Woodworking Machinery Operators should take art/design, blueprint reading, general math (arithmetic, fractions, decimals, ratios, proportions), geometry, drafting, computer-aided design, basic computer programming, and woodworking or shop courses

- Gain hands-on skills under the supervision of a professional who can show you how to use hand and power tools safely

- High school students can often take community college or vocational training classes simultaneously. Your school counselor should be able to offer details

- Get practical work experience through part-time carpentry or construction jobs (or via apprenticeships or entry-level laborer positions)

- Kumuha ng mga ad hoc na klase online, mula sa Coursera , Udemy , o iba pang mga site

- Watch related videos on YouTube channels like WOOD magazine and Rob Cosman

- Educate yourself through relevant books, magazines, blogs, and discussion forums

- Ask a working Woodworking Machinery Operator if they have time to do an informational interview with you

- Makipag-ugnayan sa mga propesyonal na organisasyon upang matuto, magbahagi, makipagkaibigan, at mapalago ang iyong network (tingnan ang aming listahan ng Mga Mapagkukunan > Mga Website)

- Simulan ang paggawa ng resume nang maaga. Panatilihin ang pagdaragdag dito habang nagpapatuloy ka, para hindi ka makaligtaan ng anuman

Note, that many employers in the skilled trades, including machine operations, conduct pre-employment drug tests. This is because the use of machines and tools can be hazardous, so employers and insurance companies want to reduce risks. For apprenticeships, unions may mandate pre-apprenticeship drug tests or random drug tests.

- Rack up as much relevant experience as you can in school or through volunteer work, part-time jobs, or an apprenticeship

- Check out job portals like Glassdoor, Indeed, USAJOBS, or SimplyHired

- Screen job ads carefully to ensure you meet the requirements

- Ituon ang iyong resume sa mga nauugnay na karanasan sa trabaho at akademiko

- Review Woodworking Machinery Operator resume templates to get ideas for formatting and phrasing

- Isama ang mga keyword sa iyong resume/application, gaya ng:

- Assembly Techniques

- Pagbasa ng Blueprint

- CAD Software

- CNC Machining

- Machine Operation

- Maintenance Procedures

- Material Handling

- OSHA Standards

- Precision Measuring

- Production Scheduling

- Kontrol sa Kalidad

- Safety Protocols

- Technical Documentation

- Tool Calibration

- Wood Finishing

- Woodworking Machinery

- Look for apprenticeship opportunities at Apprenticeship.gov

- Humingi ng tulong sa mga tauhan ng mga serbisyo sa karera ng iyong paaralan sa mga resume, kunwaring panayam , at paghahanap ng trabaho

- Gayundin, humingi ng tulong sa pagkonekta sa mga recruiter at job fair. Maaaring mayroon pa silang koneksyon sa mga lokal na unyon na nag-aalok ng mga apprenticeship!

- Kung nag-aaplay para sa isang apprenticeship ng unyon, basahin nang mabuti ang mga tagubilin sa aplikasyon bago punan ang anuman. Tandaan, "hindi inaasahan ng karamihan sa mga unyon na magiging eksperto ka sa iyong industriya," kapag nag-aplay ka para sa isang apprenticeship," ang tala ng Indeed

- Abutin ang iyong network upang ipaalam sa kanila na naghahanap ka ng mga pagkakataon

- Magtanong nang maaga sa mga potensyal na sanggunian upang makita kung irerekomenda ka nila o magsulat ng mga liham ng sanggunian

- Makisali sa mga online na forum at magtanong ng mga tanong sa payo sa karera

- Maghanap ng mga karaniwang tanong sa pakikipanayam upang maghanda para sa mga mahahalagang panayam

- At interviews, be honest and show a motivated attitude and eagerness to learn

- Palaging magsuot ng angkop para sa tagumpay sa pakikipanayam sa trabaho!

- Be ready to meet pre-employment requirements

- Woodworking Machinery Operators can work their way up by doing consistently high-quality work, paying attention to details, being on time and ready every day, and getting projects finished on time and on budget

- Talk to your supervisor about your career goals. Let them know you are willing to knock out any training your employer suggests, such as specialized certifications

- Ask about tuition reimbursement or other employer-sponsored educational benefits to cover your expenses as you continue learning about the trade

- Challenge yourself to work on more complex projects

- Always prioritize safety and never take shortcuts. One significant mishap or injury could damage your whole career!

- Demonstrate that you can be trusted to work independently. Set the example for others to follow

- Pag-aralan ang mga gabay ng tagagawa at software. Maging ang go-to na eksperto at gawin ang iyong sarili na napakahalaga

- Learn all you can from those with more experience (but also keep in mind to follow procedures as directed by your employer)

- Collaborate effectively on teams, stay focused, and demonstrate

leadership. Keep your cool under pressure, and treat everyone with respect! - Train new workers thoroughly. Their mistakes could reflect on your training abilities

- Stay engaged with professional organizations and unions

Mga website

- Apprenticeship.gov

- Architectural Woodwork Institute

- Asosasyon para sa Teknolohiya sa Paggawa

- Association of Woodworking & Furnishings Suppliers

- Mga Koneksyon sa Karera

- Mga Karpintero Southwest Administrative Corporation

- Institusyon ng Pagsasanay ng mga Karpintero

- Asosasyon ng mga Fabricator at Manufacturers, International

- Family Handyman Magazine

- Fine Woodworking Magazine

- Mga helmet sa Hardhats

- International Woodworking Fair

- Job Corps

- More Woodturning Magazine

- National Building Trades Union

- National Tooling and Machining Association

- NCCER

- Popular Woodworking Magazine

- Praktikal na Machinist

- Scroll Saw Woodworking and Crafts

- ShopNotes

- Sisters in the Brotherhood

- This Old House Magazine

- United Brotherhood of Carpenters and Joiners of America

- United Brotherhood of Carpenters and Joiners of America, Carpenters Training Fund

- Mga Karpintero sa Kanlurang Estado

- Woodcarving Illustrated

- Wood Component Manufacturers Association

- Woodcraft Magazine

- Wood Industry Ed

- Wood Industry Resource Collaborative

- Wood Magazine

- Woodsmith

- Woodwork Career Alliance of North America

- Woodworker’s Journal

Mga libro

- Machinists’ Ready Reference, by C. Weingartner and Jim Effner

- Mastering Woodworking Machines (Find Woodworking), by Mark Duginske

- Woodworking: The Complete Step-by-Step Manual, by DK

- Woodworking Basics - Mastering the Essentials of Craftsmanship - An Integrated Approach With Hand and Power Tools, by Peter Korn

- Woodworking Bible: Discover Essential Tools and Equipment to Set Up Your Homebased Workshop. Follow Step-By-Step Techniques to Create Over 50 DIY Plans and Projects, by DIY Academy

Woodworking in general is becoming more automated these days, but overall the job outlook seems stable according to the Bureau of Labor Statistics. Still, if you want to explore other options, below are several more occupations to consider!

- Boilermaker

- Building Maintenance Worker

- karpintero

- Computer Programmer

- Manggagawa sa Konstruksyon

- Operator ng Makina sa Pagputol, Pagsuntok, at Pindutin

- Drywall Installer

- Taga-install ng Sahig

- Forging Machine Operator

- Furniture Assembler

- Industrial Machinery Mechanic

- Insulation Worker

- Manggagawa ng bakal

- Mang-aalahas

- Lathe and Turning Machine Tool Operator

- Machinist/Tool and Die Maker

- Operator ng Milling at Planing Machine

- Renovation Specialist

- Rolling Machine Operator

- Roofer

- Sheet Metal Worker

- Solar Photovoltaic Installer

- Structural Metal Fabricator at Fitter

- Textile Cutting Machine Operator

- Tile at Stone Setter

- Welder

Newsfeed

Mga Tampok na Trabaho

Mga Online na Kurso at Tool